We conducted comparison test between conventional method and SSU method, and we found out following results.

- Reduce paint consumption: Maxmim 43%

- Higher density of film:Maximum 45%

- Better finish

【Test results】

1.Solvent-borne coating (Urethane paint:1/10 formulation)

Manual coating

| Manual spray (by hand) |

Carrier gas | Solvent content | Spraying gun pressure (MPa) |

Paint consumed (gr) |

Layer number | Finish | Paint reduction (%) |

|---|---|---|---|---|---|---|---|

| Conventional(Normal press.) | Compressed air | 70% | 0.250 | 36.1 | 4 | Good | - |

| Conventional (Lower press.) |

Compressed air | 70% | 0.175 | 27.0 | 5 | No Good | - |

| SSU (Lower press.) |

SSU treated air | 70% | 0.175 | 25.5 | 4 | Good | -30 |

| SSU (Lower press. + high viscosity) |

SSU treated air | 35% | 0.175 | 20.6 | 4 | Good | -43 |

Automatic coating

● By using the same paint formulation under the same spray volume, film with SSU was thicker than that without SSU by 45%.

| Auto spray (robot-equipment-1) | Carrier gas | Solvent content | Sparying gun pressure (MPa) |

Paint consumed (gr) |

Layer number | Finish | Film thickness (μm) |

Improvement of thickness(%) |

|---|---|---|---|---|---|---|---|---|

| Conventional (Normal press.) |

Compressed air | 70% | 0.250 | 46.7 | 2 | Good | 19.8 | - |

| SSU (Lower press. + higher viscosity) |

SSU treated air | 50% | 0.175 | 46.7 | 2 | Good | 28.7 | +45 |

● In case of the same film thickness gained by both with SSU and without SSu, total paint consumption with SSU was drastically economized by 34%.

| Auto spray (robot-equipment-2) |

carrier gas | Solvent content | Sprying gun pressue (MPa) |

Paint consumed (gr) |

Layer number | Finish | Film thickness (μm) |

Pain reduction (%) |

Paint Viscosity(sec) |

|---|---|---|---|---|---|---|---|---|---|

| Conventional (Normal press.) |

Compressed air |

70% | 0.250 | 43.0 | 2 | Good | 11.0 | - | 11.7 |

| SSU (Lower press. + higher viscosity) |

SSU treated air |

50% | 0.175 | 28.3 | 2 | Good | 11.3 | -34 | 14.5 |

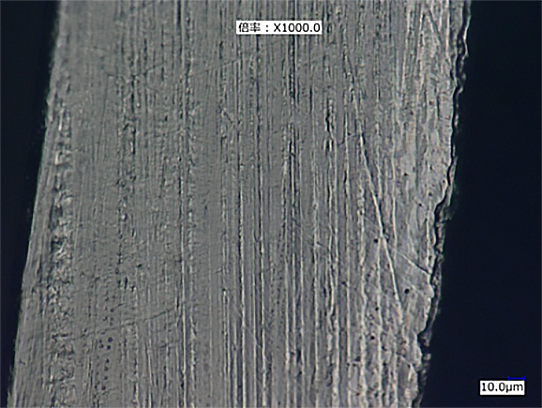

Comparison test results using SSU and conventional coating method (powder coating)

In case of powder coating, the same approach as the solvent cannot be used, but when comparing the cross sections of the coating film even under the same coating conditions, it was confirmed that the film density was improved by SSU coating.

By using SSU, the powder coating material can be adhered to the target object to be coated efficiently and at high density. It can be seen that when SSU (right photo) is used, the air layer remaining and internal in the coating film is less and the coating film density is higher than that of the conventional coating (left photo). As a result, the effect of SSU coating can be expected in terms of physical properties such as secondary adhesion.

We also have data on powder paints (fluorine-based: ETFE) and water-based paints (fluorine-based: PTFE: solid content 30%). Please register as an SSU member and have a look.